- Easily paired with other Extraction modular offerings for rapid deployment and speed to market

- Modular design provides a cost-effective path to address any growth needs that arise

- High-efficiency design lowering both capital expenditures and operating expenses while improving throughput

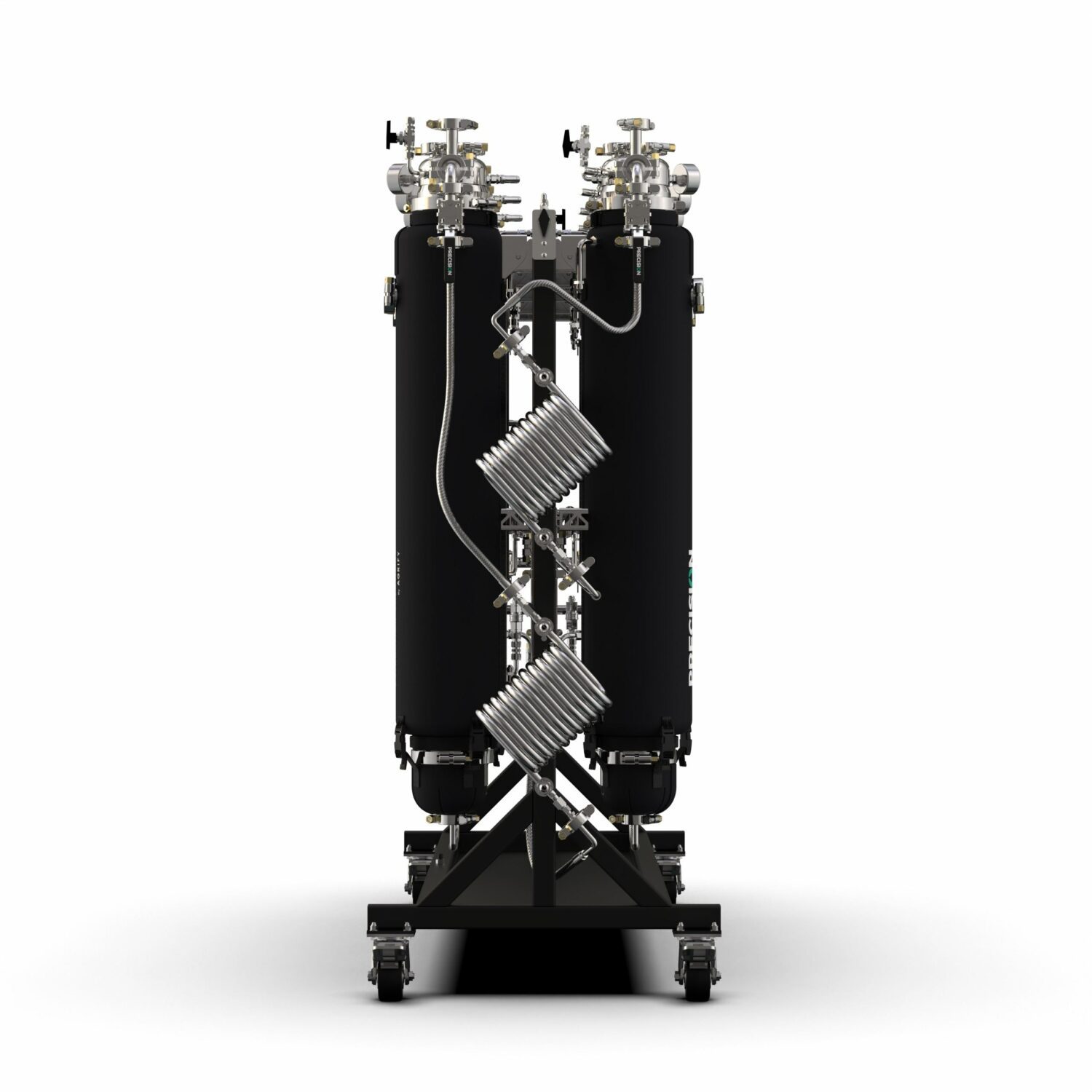

- Liquid jacketed columns enabling low temperature operation for improved product quality

- Included material socks for faster material changeover between run cycles increasing daily output

- The integrated PX10 molecular sieve columns for inline solvent desiccation removes moisture from solvent preserving the solvent’s effectiveness

- Dedicated sight glasses in all columns makes process inspection fast and intuitive

- Incorporating a maintenance-forward design, universal parts minimize the expense of stocking spares

- Two inline CRC columns provide flexibility in purifying extract through customizable filtration media remediation removing a wide variety of different contaminants in real time

- Easy-to-use two-bolt compliant tri-clamp service connections

- Two EXERGY tube-in-tube heat exchanger’s enabling rapid solvent recovery

- Class 1, Division 1 (C1D1) Compliant

- Designed for GMP integration

- PSI Certified – 50 State Compliant

- Designed to ASME standards

- Designed to meet 3A sanitary standards

- NFPA 58 LPG

- Engineer Peer-Reviewed

- Assembled in USA

Pre-Approved for Easy Certification

The PX10 Hydrocarbon Extractor is pre-approved and ready for professional engineers to field verify in all 50 states, so you can get operational faster. In partnership with PSI (Pressure Safety Inspectors), our extractors come with a PSI technical report certification and a field verification voucher to meet your state and local regulations.

Once your system is installed by a Technician, simply call PSI and schedule your field verification. Simple as that!

CAPACITY PER BATCH

10 lb

BATCH CYCLE TIME

35 minutes

CAPACITY

Up to 160+ lb per 8 hr Shift

DIMENSIONS (approx)

101″ L x 30″ W x 76″ H

WEIGHT

1350 lb

MAWP

350 PSIG

1-Year

Precision offers the following on-site product installation and training with experienced extraction technicians:

- Install & Basic Training

- Craft Concentrates Training

- Inline Color Remediation

- Extract Product Engineering